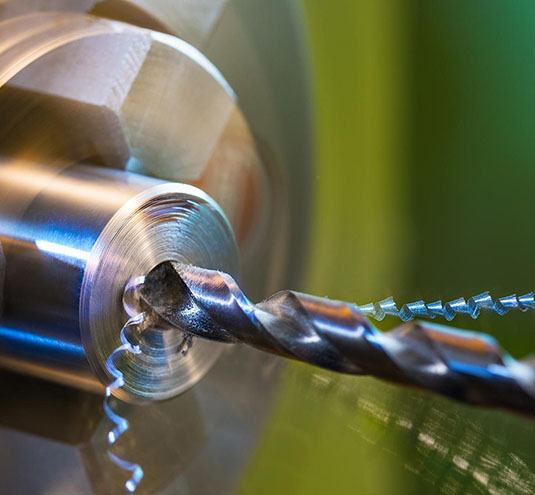

A drill bit or drilling bit is designed to drill holes in materials such as wood, metal, plastic, ceramic tile, porcelain and concrete.

- +8619957767763

- dennis@bestwin-tools.com

- Mon to Fri 8:00 am to 6:00pm

- ISO9001:2015

Drill bits

Hole Saws

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece.

Power Tools

Power tools are a great addition to your workspace, they provide a faster, cleaner, less hassle-free alternative to hand tools.

Ratchet Set

BESTWIN Tools Co. Ltd specializes in providing the high quality and cost effective Ratchet Set Series.

One stop hand tools solution

Dedicated to provides cost-effective

drilling bits,hole saws and power tools.

ISO 9001:2015 CE Verified

Professional drilling tools, hole saws and power tools supplier for global wholesalers.

BESTWIN Tools Co. Ltd specializes in providing the high quality and cost effective drilling bits, hole saws, and power tools globally. All tools work well on any common hard materials such as woodworking, ceramic, concrete, steel, diamond, marble glasses and so on. No matter what job result you required, BESTWIN tools give you the most reliable solutions.

Powerful Hand Tools Solutions

High-lighted BESTWIN Drilling Bits,

Hole Saws and Power Tools

Looking for professional drilling bits, hole saws and power tools supplier? Quote the latest price for high-lighted BESTWIN drilling bits, hole saws and power tools right now.

Cordless Car Washer BS1101

The Cordless Car Washer BS1101 is a simplified cleaning tool that allows you to easily remove any ir...

BESTWIN Quick change Arbors

BESTWIN Quick change Arbors allow quick, tool-free changeover between different sizes and types of h...

BESTWIN HSS M42 Bi-metal Hole saw with QC arbors

BESTWIN HSS M42 Bi-metal Hole saw with QC arbors is used to cut perfectly round holes in various mat...

BESTWIN M42 Bi-metal Hole saw

BESTWIN M42 Bi-metal Hole saw with hex adapter and spot drill for wood iron sheet pipe plastic. The ...

SDS Plus Electric hammer bit

The SDS Plus Electric hammer bit is specially manufactured for drilling in hard materials such as co...

Rotary hammer core bits

Rotary hammer core bits make it suitable for drilling in materials such as masonry, wood and metal a...

Cordless Drill DW6021C

The Cordless Drill DW6021C is a compact cordless drill-driver with Active Torque Control for everyda...

Cordless Anole Grinder BS6125

The Cordless Anole Grinder BS6125 is a lightweight cordless angle grinder that is easy to handle and...

Cordless Rotary Hammer BS2600

The cordless hammer BS2600 is a reliable tool that will work for drilling with or without a lock, pe...

HZF-911947pc ratchet screwdriver set

HZF911947pc ratchet screwdriver set includes all popular socket and bit sizes, and packed in a sturd...

HZE-10045 22pc Ratchet Screwdriver Set

HZE-10046 18pc Ratchet Screwdriver Set

Quick Release Arbor

The Quick Release Arbor is a high performance thin wall hole saw kit consisting of a steel body and ...

Borderless light hole set

Used for pre embedding and opening of lamps, suitable for gypsum board, wooden board, acrylic, etc

Leading Drilling Bits and Hole Saws Manufacturer

Drilling Bits, Hole Saws and Power Tools

Find and buy the effective and low cost drilling bits, hole saws, power tools and accessories for wholesalers, factories, projects, etc. Work with woodworking, concrete, steel, ceramic, diamond and marble glasses with ease!

Woodworking series

Wood drilling bits refers to drilling bits that are designed to drill and make holes on wood easily.

Electric hammer bit

A drill bit or drilling bit is designed to drill holes in materials such as wood, metal, plastic, ceramic tile, porcelain and concrete.

Multifunctional drill bit

A drill bit or drilling bit is designed to drill holes in materials such as wood, metal, plastic, ceramic tile, porcelain and concrete.

Chisel

A drill bit or drilling bit is designed to drill holes in materials such as wood, metal, plastic, ceramic tile, porcelain and concrete.

Router Bit

A drill bit or drilling bit is designed to drill holes in materials such as wood, metal, plastic, ceramic tile, porcelain and concrete.

M42 BI-Metal Hole Saws

M42 BI-metal hole saws are made from M42 high-speed steel with 8% premium cobalt and a rigged solid back plate.

Hole Saw Arbors

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

H.S.S. Hole Saws

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

T.C.T. Hole Saws

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

Hollow Hammer Core Bits

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

Diamond Hole Saws

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

Kit Series

A hole saw, also known as a hole cutter, is a saw blade of annular shape, whose annular kerf creates a hole in the workpiece, high quality hole saws from BESTWIN TOOLS

Li-ion Cordless Series

Power tools also called electric tools, are the choice of professionals thanks to their long-life and powerful performance.

AC Powered Tools

Air tools also called Pneumatic tools, are the choice of professionals thanks to their long-life and powerful performance.

BESTWIN

Industries We Serve

BESTWIN Tools Serves and Applied in Many Industries

BESTWIN Tools Co.,Ltd. provides high quality, durable and cost-effective drilling bits,

hole saws, power tools applied in many industries such as wood working, construction, metal cutting, diamond processing, marble glass cutting etc.

A Leading Industrial BESTWIN Tools Supplier

Why Chose BESTWIN TOOLS?

BESTWIN Tools Co.,Ltd. is a professional hand tools and accessories provider providing high quality, effective and reliable drilling bits, hole saws, power tools and other tool parts globally.

Leading industrial drilling bits Supplier

As a leading industrial drilling bits supplier, BESTWIN Tools Co., Ltd aims to provide the best quality and low cost drilling bits for all working materials and conditions.

High Quality and Durable Drilling Bits

If you need high quality drilling bit, we have it. BESTWIN Tools Co., Ltd. is a professional carbide drilling bit supplier provides the hardest and durable drilling bits.

Best Hole Saws for Home and Industrial Use

Qualified hole saws, hole saws drill bits, drills for sale, handy hole cutter for any working conditions and needs. Buy them in bulk online from BESTWIN Tools Co., Ltd.

Pick up professional and high quality

drilling tools from BESTWIN TOOLS!

Advanced Drilling Tools, Hole Saws Technology

Latest Drilling Tools News & Technology

News and knowledge about drilling tools, hole saws, power tools for any hard material cutting drilling,

such as metal, steel, concrete, diamond, marble glasses, woodworking and so on.

Corded vs. Cordless Chainsaws: Weighing ...

Discover the key differences between corded and cordless chainsaws, as we delve into the pros and co...

Cordless Chainsaw Accessories: Enhancing...

Cordless chainsaw accessories are an excellent addition to your chainsaw arsenal, ensuring safety, p...

Cordless Chainsaws for Homeowners: Why G...

Discover why cordless chainsaws are the future of yard work for homeowners. Learn about the numerous...

Get a Quote

Choose the Best Drilling Bits,

Hole Saws for Your Work

Describe your needs and quantities in detail.

Get a Quote from BESTWIN TOOLS

Get a quote on the latest price of drilling bits, hole saws, power tools and accessories. We will reply within 48 hours.